HAND-SWAGED BULLETS

When it comes to precision shooting, every detail matters. Every component plays a crucial role in achieving accuracy and precision, from the rifle you choose to the ammunition you use. That's why more and more precision marksmen are turning to hand-swaged bullets for superior performance and unparalleled precision.

Ammerman Arms is here to provide dedicated marksmen with custom precision bullets handmade in the USA, with the highest quality materials and the most exacting standards. Learn how we handcraft every single one of our projectiles and how our dedication carries over to your performance.

What Are Hand-Swaged Bullets?

Hand-swaging is a process used to create bullets with unparalleled precision and quality. Unlike mass-produced bullets manufactured in large quantities, hand-swaged bullets are meticulously crafted one at a time. This attention to detail ensures that each bullet meets the specifications required for optimal performance.

A lead wire is used as the primary material for creating the bullet in the swaging process. The wire is meticulously inserted into a die and shaped under high pressure. This process allows for complete control over the dimensions and weight of the bullet, and with one of our master craftsmen at work, every bullet is made to match standards perfectly.

The Swaging Process

The swaging process begins with creating a die, a tool to shape the bullet. The die is carefully machined to the exact dimensions required for the desired bullet type and ogive.

This die is then placed into a press, along with a punch and the core material that will be formed into the bullet core. The lead wire for the core is then placed in the die, and a punch is used to shape the wire under high pressure generated by the press. This creates the basic form of the core and desired weight.

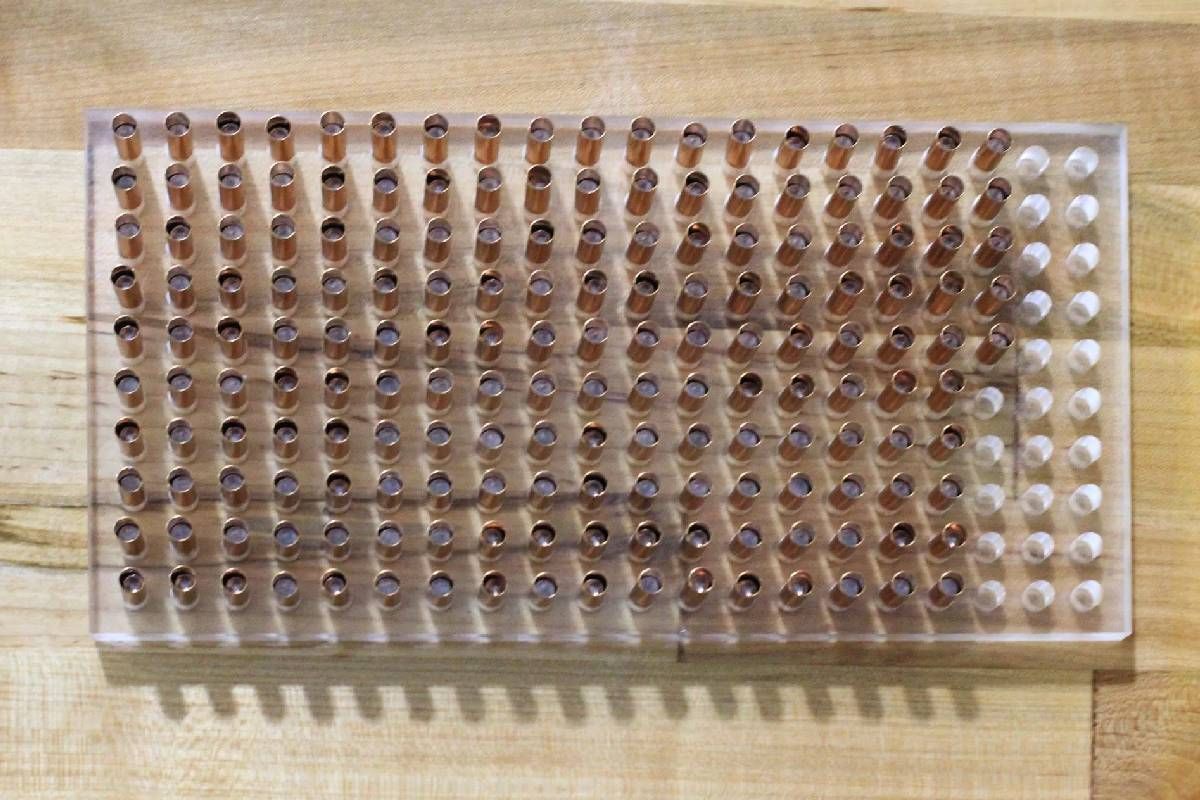

After the initial shaping, the bullet core is inspected, and any imperfections or inconsistencies are addressed. Skilled craftsmen carefully examine each bullet after every stage of the process, checking for any deformities or variations. This manual inspection ensures that only the highest-quality bullets make it to the next step of the process.

After the lead core is formed and inspected, it is inserted into the copper jacket. From there, it goes through the core seat form die for the base of the desired formed projectile. Then is pressed to form the projectile's ogive and finished bullet. The finalized bullets undergo a final inspection to guarantee their quality and uniformity before they are packaged for shipping to you!

The Benefits of Hand-Swaged Bullets

Hand-swaged bullets offer a multitude of benefits that set them apart from mass-produced alternatives:

Far Superior Accuracy and Precision

One of the most significant advantages of hand-swaged bullets is their exceptional accuracy and precision. The meticulous attention to detail and the use of high-quality materials in the swaging process result in bullets that have tight tolerances and consistent performance. Unlike other manufacturing methods, swaging puts the bullet materials under such high pressure that there is no chance for voids or other imperfections to form. Marksmen can rely on these bullets to deliver exceptional accuracy shot after shot, giving them a competitive edge in precision shooting.

Consistency and Uniformity

Hand-swaged bullets are renowned for their consistency and uniformity. Each bullet is individually crafted, allowing precise control over its weight, shape, and dimensions. This level of consistency ensures that each bullet performs in the same predictable manner, eliminating variations and producing reliable results. With every bullet being handled by a human, any marksmen can trust that each round will behave consistently, fostering confidence in their shooting abilities.

Customization Options

Hand-swaging also allows for a greater level of customization. Precision marksmen can work closely with bullet manufacturers like Ammerman Arms to create bullets tailored to their unique needs and preferences. Customization options can include bullet shape, length, and weight adjustments catering to specific ballistic requirements. This level of customization and attention to detail empowers sportsmen and competitive shooters to fine-tune their rounds to achieve optimal performance.

Made in the USA with Pride

At Ammerman Arms, we take great pride in crafting our hand-swaged bullets in the USA. We source the finest American-made materials and rely on skilled craftsmen who are passionate about their work. By manufacturing our bullets locally, we maintain strict quality control and ensure that every bullet meets our exacting standards.

Choose Ammerman Arms for Superior Hand-Swaged Bullets

Ammerman Arms is the premier choice for hand-swaged bullets for precision shooters, hunters, and sportsmen who need rounds they can trust. Our commitment to precision, quality, and consistency is unmatched, and our bullets are trusted by marksmen nationwide.

Trust in Ammerman Arms to deliver the highest-quality hand-swaged bullets on the market, made with pride in the USA. Check out our catalog for yourself, or contact us to see what we can do for you.

Sign up for our mailing list

Sign up for Our

Mailing List

Email Sign Up

We will get back to you as soon as possible.

Please try again later.

Quick Links

Resources

Ammerman Arms

Website by Creekmore Marketing